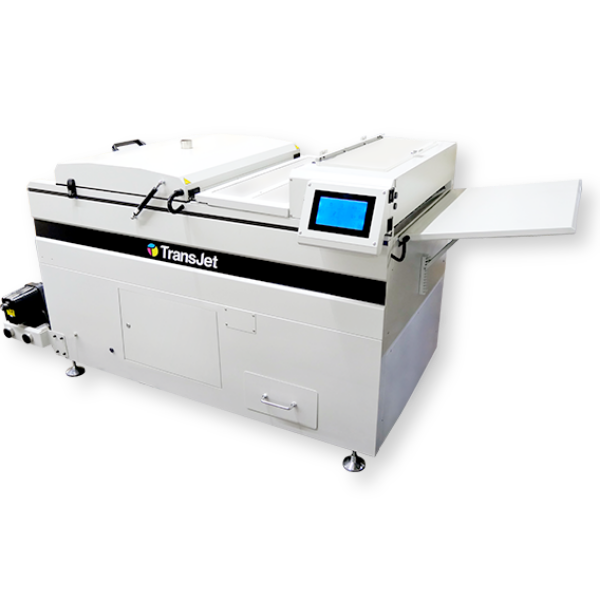

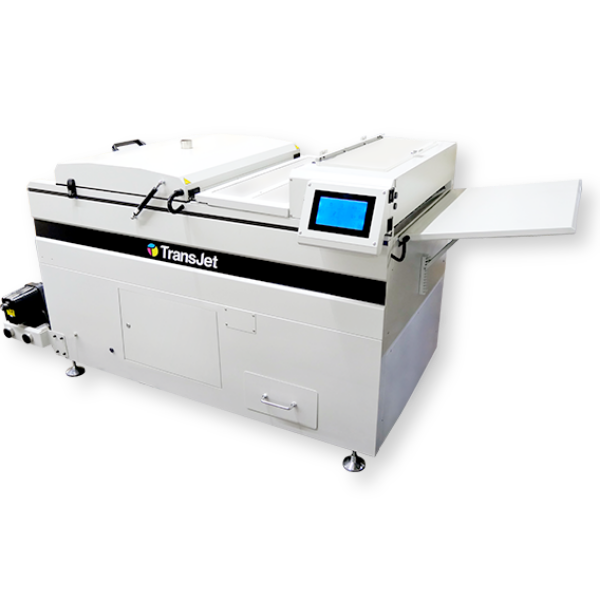

DTTS-P600 (printer)

Trans Jet DTTS-600 has also established a new domestic maintenance and support network for its release. IMAGEMAGIC will also support startups and businesses in other industries with a system that allows them to order consumables such as transfer sheets and ink on the Web.

DTTS-P600 (printer), DTTS-BF600 (binder applicator), and heat press machine.With these three items, you can start a full-scale print business.

DTTS-P600 is equipped with a Japanese-made ink uniquely developed and optimized for DTF printers. This ink eliminates discharge failures in low-temperature and low-humidity environments characteristic of DTF printers and realizes high-quality prints.While maintaining the same high quality durability as before in terms of fastness to rubbing and washing, the ink is filled in a vacuum aluminum pouch to prevent deterioration. The pouch can be refilled directly from the pouch, eliminating the need to refill the printer every time, and enabling smooth continuous output.

Trans Jet prints with the same quality as a professional, no matter which model is used. Of course, the operator does not need any printing experience. Until now, a certain level of knowledge was required for inexperienced workers to start T-shirt printing. For example, DTG inkjet printing requires pre-treatment depending on the color of the material, and the quality of the T-shirt varies depending on the type of fabric, and the printing quality is completely different depending on how the pre-treatment is applied, requiring a lot of know-how. Also, even in the case of conventional transfer printing, the type of transfer sheet changed depending on the type of material, but with this on-demand transfer, all the same materials can be used to make original prints on various products and as long as you learn how to heat press, anyone can print immediately with this revolutionary device that allows anyone to quickly print as long as they know how to heat press.

Trans Jet operates automatically from printing to powder sprinkling and sheet winding through a conveyor. Automatic operation is possible for up to 3 hours with the stock system, but with the addition of an optional tower and dedicated jig, automatic continuous operation for 5 hours or more is possible.

Trans Jet” can transfer print not only on white cotton T-shirts and dark-colored T-shirts such as black T-shirts, but also on various materials such as polyester T-shirts, nylon products, wood, non-woven fabrics (with conditions) and mesh materials. If you have any items that you would like to print on, please contact us. If you have an item that you would like to try printing on, please give it a try.

Unlike DTG printing (inkjet printing), transfer printing is an extremely durable printing method that is widely used for uniforms. IMAGEMAGIC has established quality standards for prints, and releases prints that have passed 103 methods of testing for dry rubbing, wet rubbing and wash durability. DTG prints (inkjet prints) are just on the verge of passing the department store standard durability test, but on-demand transfer prints can affordably pass the test.