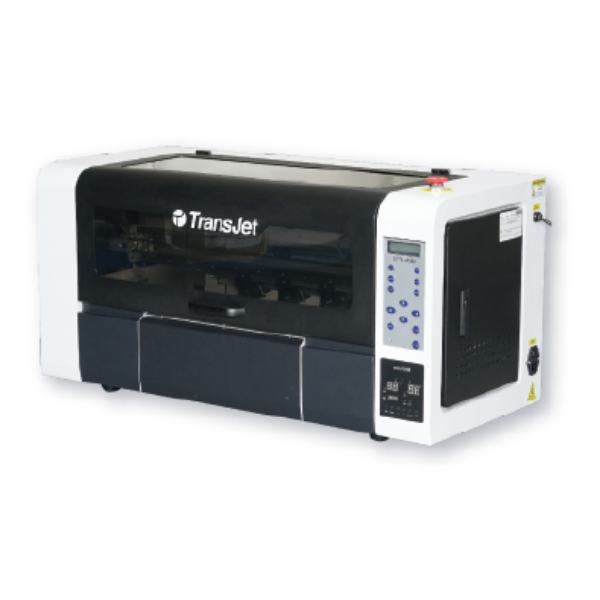

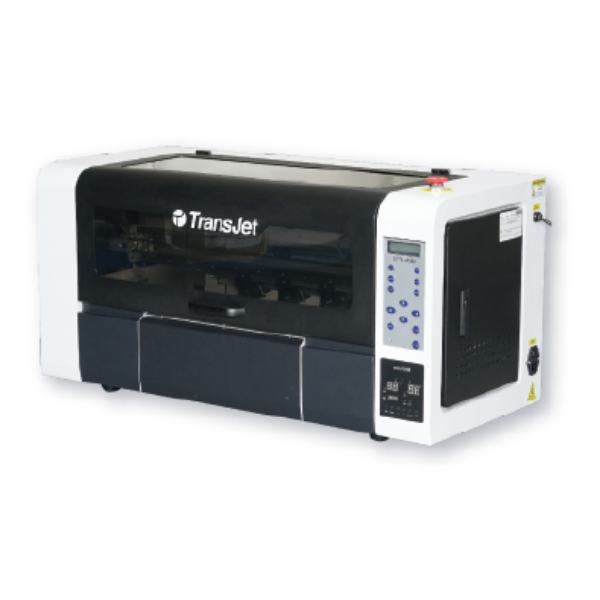

DTTS-P302(printer)

Small-scale printing businesses and shops/factories. It also enables vertical start-up of new business by different industries. This compact model is designed to save space, yet offers speedy & high image quality.

Many of the small DTF models on the market are entry-level models, and their introduction at factories has been discouraged due to concerns about stable operation and slow speed caused by the simplicity of the head structure. However, by adopting the same high-performance head as the mass-produced DTTS-P600 factory model and installing a Japanese-made pouch ink supply system, we were able to achieve a printing speed of 8.39 m2/h on an actual measurement basis even at standard settings, with no nozzle clogging and stable operation. The printer stand is also equipped with casters as standard equipment, along with the binder applicator (DTTS-BF302), making it easy to move the printer after installation.

The DTTS-P302 is equipped with a proprietary Japanese-made ink optimized for DTF printers, which eliminates discharge defects in low temperature and low humidity environments characteristic of DTF printers and realizes high-quality printing. While maintaining the same high quality durability as before in terms of fastness to rubbing and washing, the ink is filled in a vacuum aluminum pouch to prevent deterioration. The pouch can be directly refilled with ink, eliminating the need to refill the printer every time, and enabling smooth continuous output.

The ink used in the DTTS-P302 can be provided at a low cost.In particular, the price of white ink, which has been pointed out as having a high unit cost in the market, is the same as that of color ink. The price of white ink, which has the greatest impact on production costs due to the nature of DTF, which uses a large amount of white ink, has been kept low, making it possible to be competitive even with small-lot production such as on-demand printing. This will contribute to the expansion of the DTF market, as it can be used in combination with space-saving printers to contribute to the vertical launch of new businesses by small-scale printers, stores and factories and other different industries.

Until now, most small machines have been simple devices that could not produce complete products or some materials, but the “Trans Jet” can print on dark-colored T-shirts, polyester and nylon materials.

Trans Jet” can transfer print not only on white cotton T-shirts and dark-colored T-shirts such as black T-shirts, but also on various materials such as polyester T-shirts, nylon products, wood, non-woven fabrics (with conditions) and mesh materials.If you have any items that you would like to print on, please let us know.If you have an item that you would like to try printing on, please give it a try.

Unlike DTG printing (inkjet printing), transfer printing is an extremely durable printing method that is widely used for uniforms. IMAGEMAGIC has established print quality standards and releases prints that have passed 103 methods of testing for dry rubbing, wet rubbing and wash durability. While DTG prints (inkjet prints) are just on the verge of passing the department store standard durability test, DTF prints can pass the test with a comfortable margin.